RIGO (Shanghai) Technology Co., Ltd.

RIGO (Shanghai) Technology Co., Ltd.

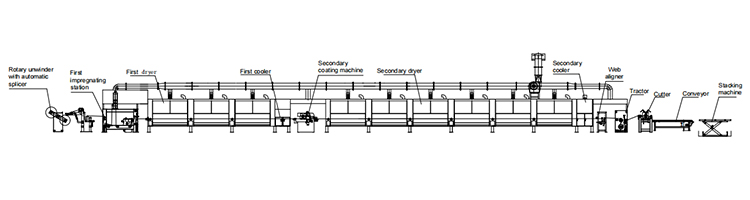

Introduce to Melamine Paper Impregnation Line

The two-stage melamine paper impregnation line is widely used for secondary processing in the wood-based panel industry. It can be used for the melamine impegnated paper for the furniture boards; impregnated overlay paper, balance paper, and flooring decorative paper for the laminate flooring; impregnation drying of the phenolic film paper for building formwork. The running speed can more than 50m/min. And the ability to cut and stack the dried paper to the required length.

Un-winder, First impregnating station, Secondary coating machine, Dryer, Cooler, Web aligner, Tractor, Paper cutter, and Stacking system.

Unwinder

Unwinder with air-swelling shafts(or non-shaft) to continuously unwind and produce, and keep the correct paper tension constant through the automatic regulating mechanism.

Automatic splicer

Automatically paper splicing from the top. Stick the new paper web to the old paper if the roll is changed and cut off the old paper. Two edge cutting devices for the edge trimming, can save resin.

First Impregnating Station

It consists of a frame, S-roller, backing rollers, metering rollers, glue basin, etc. The paper is pre-impregnated and the glue pick-up is controlled by adjusting the gap between the metering rollers.

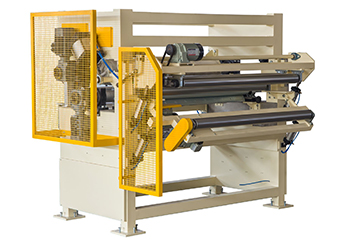

Secondary Coating Machine

Newly designed frame for more stable operation. The smoothing roller frame can be raised in its entirety to facilitate the cleaning of the anilox rollers. Two times resin covering onto both sides of the paper according to process requirements.

Dryer

Air flotation type dryer, drying the paper after first impregnator and secondary coator. The heating medium can choose to use thermal oil or natural gas. Special frame construction and insulation for energy savings.

Cooler

Attached to the back of the dryer to cool the paper. Lengths can be customized on request and equipped with a cooling device.

Enable accurate and reliable web tension control and aligning of the web come from dryers.

Rotary Cutter

Precise sheet cutting by means of START-STOP function and spin-type knife design to ensure optimized wear combined with excellent cutting quality.

Stacking System

Consists of a belt and lifting table for the stacking of finished paper. A double-layer automatic stacking system can be used as an option depending on the requirements of the production process.

As the first manufacturer in China to use natural gas as a heating medium, the RG series paper impregnating and coating line has a wealth of experience in this area and, together with excellent insulation technology, is able to achieve energy savings of 10-15% compared to other manufacturers. The fine workmanship ensures high stability during the operation and the precision of the resin pick-up.Production line made modular for easy installation by the customer.

Small upfront investment, more widespread use, not limited by energy.

Natural gas

Environmentally friendly, the oven heats up and cools down quickly, saving energy, while being highly productive.

Rigo uses state-of-the-art software programs, such as Siemens¡¢ABB and Schneider.

Modern failsafe PLC and modern bus technology (Profinet, Profisafe) are Rigo standard.

The comfort touch panels are displaying all important data of the plant at a glance and provide quick access to all process parameters. The process masks are continuously focused on the process and in case of a problem or interruption a high volume of information can be provided, in order to localize the reason for the disturbance. Moreover Rigo has got a new remote maintenance concept with simplified software, which improves maintenance and troubleshooting.

1. Complete impregnation line

2. Single units( unwinder, impregnating station, dryer, coating machine, coole, web aligner, cutter, conveyor, lifting table)

3. Resin making equipment and resin mixing system

4. Heat recovery system and air treatment

5. Spare parts

6. Laboratory equipment( test press machine, manual impregnation device, test device, and etc)

7. Technology transfer(resin formulations, impregnation technology, plant planning)

What is a melamine paper impregnation line?

A melamine paper impregnation line is a production line used to impregnate decorative paper with melamine resin, which enhances its durability and aesthetic appeal. This treated paper is commonly used in the manufacture of laminate flooring, furniture, and other decorative surfaces.

How does a melamine paper impregnation line work?

The process involves feeding decorative paper through a series of rollers where it is saturated with melamine resin. The impregnated paper then passes through a drying oven to cure the resin, resulting in a tough and durable decorative layer.

What are the advantages of using melamine impregnated paper?

Melamine impregnated paper offers several benefits, including enhanced scratch and abrasion resistance, resistance to moisture and chemicals, UV stability, and a wide range of decorative options.

What types of decorative papers can be used in this process?

Various types of decorative papers, including solid colors, wood grains, stone patterns, and custom designs, can be used in a melamine paper impregnation line, offering versatility in the final product.

What are the key components of a melamine paper impregnation line?

Key components typically include unwinding stations for paper rolls, resin application systems, drying ovens, cooling zones, tension control mechanisms, and winding stations for finished rolls.

What are the quality control measures in place during production?

Quality control measures may include monitoring resin consistency, temperature control in the impregnation and curing processes, inspection of finished product for defects, and adherence to specified thickness and gloss levels.

What are the maintenance requirements for a melamine paper impregnation line?

Regular maintenance of rollers, heating elements, and other components is essential to ensure consistent performance and product quality. Cleaning of resin application systems and periodic calibration of equipment may also be necessary.

Can the production line accommodate custom specifications and designs?

Yes, modern melamine paper impregnation lines are often equipped with features that allow for customization of decorative patterns, colors, and surface textures to meet specific customer requirements.

What are the safety considerations associated with operating such equipment?

Safety measures may include proper training of operators, installation of safety guards and emergency stop mechanisms, adherence to electrical and fire safety standards, and routine inspection of equipment for potential hazards.