Introduce to the intelligent glue mixing system

What is an intelligent dispensing system?

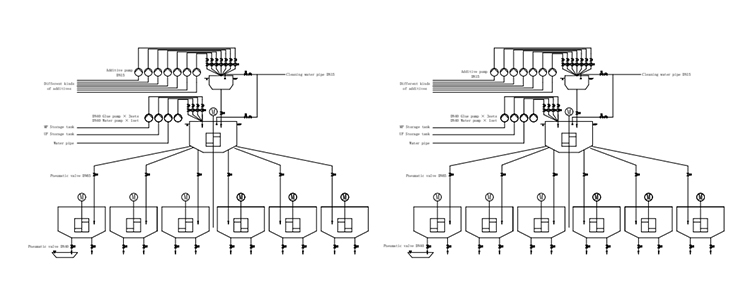

It is an automatic glue mixing and supply system for impregnating and coating lines. It can realize different glue supply for the glue used in the first impregnating station, spraying machine, and secondary coating machine. According to the actual working conditions, it is necessary to extract different types of additives and raw resin with different ratios, so as to configure resins suitable for different sections. And the automation of the glue dispensing system of the production line is realized, which ensures the stability of glue dispensing in each section.

What are the main components of the intelligent dispensing system?

PLC control program, weighing system, tank, mixing system, liquid level indicator, pump and glue storage tank and other components.

What are the advantages of the intelligent dispensing system?

1. Product quality is stable

Additives and raw rubber are weighed and mixed by a weighing system, which ensures the accuracy of the ratio of raw rubber and additives in resin and ensures the quality of product production.

2. High production flexibility

According to the different ratios of additives and raw rubber, products that meet the different needs of the market can be produced, and the production flexibility is high.

3. Cost saving

Additives and raw rubber are accurately measured by the weighing system and then added to the mixing tank to reduce waste and save costs.

4. Store more recipes

Dozens of different recipes can be stored according to process requirements

Customer plant example

How can we support your business

1. Complete impregnation line

2. Single units( unwinder, impregnating station, dryer, coating machine, coole, web aligner, cutter, conveyor, lifting table)

3. Resin making equipment and resin mixing system

4. Heat recovery system and air treatment

5. Spare parts

6. Laboratory equipment( test press machine, manual impregnation device, test device, and etc)

7. Technology transfer(resin formulations, impregnation technology, plant planning)